Computer Simulation of the Hydraulic Control System for Exoskeleton

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Torque for actuator weight estimation (Nm) |

Unit weight (kg) |

No. of parts |

|

|

Weight of actuator @ shoulder |

296.1 |

10.00 |

2 |

20.00 |

|

Weight of link from shoulder to elbow |

- |

4.29 |

2 |

8.58 |

|

Weight of actuator @ elbow |

164.4 |

6.00 |

2 |

12.00 |

|

Weight of link from elbow to wrist |

- |

2.16 |

2 |

4.32 |

|

Weight of actuator @ wrist |

- |

3.00 |

2 |

6.00 |

|

Weight of hand |

- |

3.00 |

2 |

6.00 |

|

Weight of supporting bracket @ back |

- |

5.61 |

1 |

5.61 |

|

Weight of components @ back |

- |

20.00 |

1 |

20.00 |

|

Weight of actuator @ hip |

403.8 |

15.00 |

2 |

30.00 |

|

Weight of link from hip to knee cap (thigh) |

- |

4.67 |

2 |

9.34 |

|

Weight of actuator @ knee |

370.1 |

12.00 |

2 |

24.00 |

|

Weight of link from knee cap to ankle (calf) |

- |

4.39 |

2 |

8.78 |

|

Weight of actuator @ ankle |

370.1 |

12.00 |

2 |

24.00 |

|

Weight of foot |

- |

2.50 |

2 |

5.00 |

|

|

|

|

|

|

|

Weight of exoskeleton (kg) |

183.63 |

|||

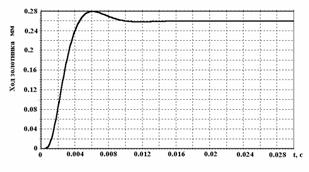

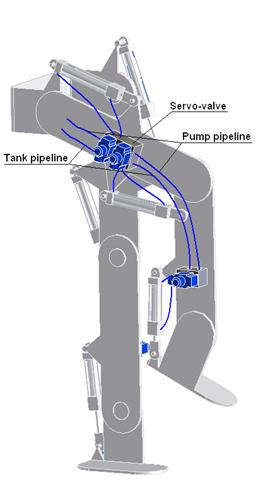

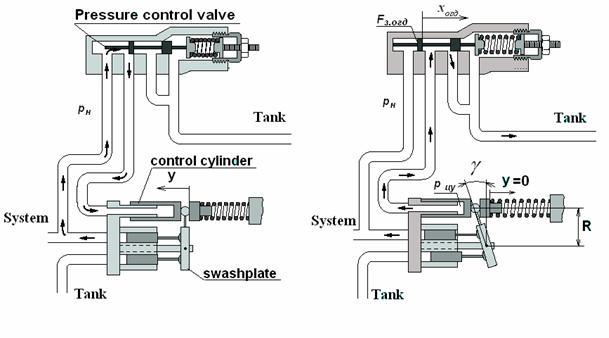

Hydraulic

Power Pack

Hydraulic power pack includes a pump with

pressure regulator. Continuous flow of pressurized fluid at set pressure is

supplied by the pump. Energy characteristics of the hydraulic system with pump

with pressure control is shown in Fig.5a.

In Fig.4a, the basic diagram of the pump

with a pressure-control valve, manufactured by Rexroth A10 VSODR, is presented.

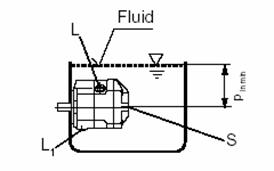

For the improvement of dimensional characteristics and configuration of a

hydraulic drive, and also with the purpose of improvement of thermal balance,

it is better to place the pump in a tank with a working fluid (Fig.6).

As flow control equipment, servo

directional valve, which are widely used in robotics and aerospace, are

considered. They have relatively small dimensions approximately 80õ46õ80 mm and

mass ~ 0.64kg, with high dynamic characteristics.

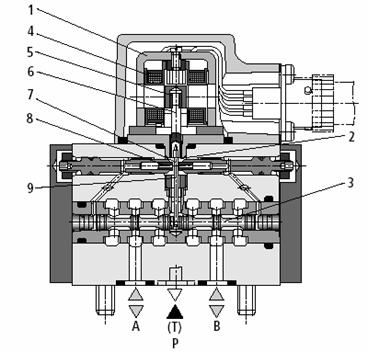

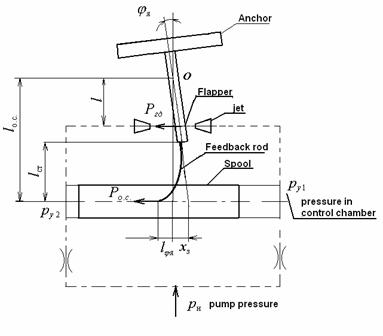

Electric-hydraulic amplifiers (servo

valves) with the mechanical feedback have wide

applications in hydraulic actuators. A

schematic diagram of a servo valve is shown in Fig.7,8. The servo valve

represents a combination of electromechanical converter (EMC) (1), the

hydraulic amplifier of a jet-flapper type (2) and a spool, which is connected

with the flapper by elastic feedback rod. Jet and flapper together represent an

adjustable throttle, resistance of which can be changed by changing the

distance between jet and flapper.

When an electric signal is applied to EMC,

an electromagnetic force is developed and this in turn rotates the armature

core. The angle of rotation depends on the level of input voltage. Along with

the armature, the flapper and the feedback spring also rotate, thus changing

the distance between the flapper and the jet. Due to this, the resistance of

adjustable throttles changes resulting in a pressure differential at the end

faces of the spool (3). This pressure differential causes the spool to move

from its neutral position, thus opening the flow ports of the spool casing, to

allow fluid flow. The movement of spool continues till the moment from the

feedback rod becomes equal to the electromagnetic moment of the armature. Thus

a constant flow of fluid through the valve is maintained as long as the input electric

signal is maintained constant. The flow is proportional to the input electric

signal. Fig.7,8 shows the Electric Hydraulic Amplifier (EHA) stage.

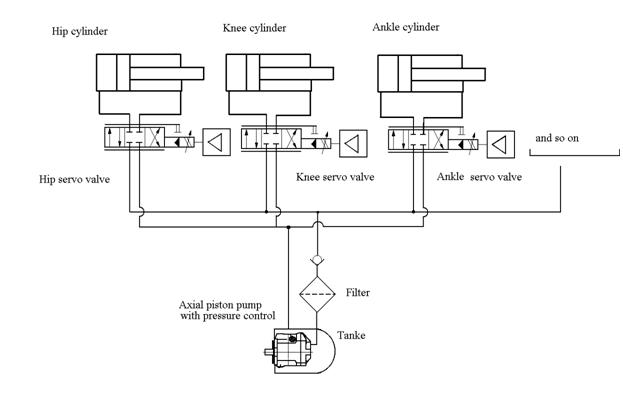

Since each part of exoskeleton requires

independent motion, they need to be controlled individually with dedicated

control valves and control strategy. The proposed hydraulic circuit diagram for

the exoskeleton (for 3 joints) is shown

in Fig.9. It includes the power

pack, hydraulic cylinders, and servo valves.

Estimated weight of elements of

various elements of the proposed 10 d.o.f. exoskeleton is given in Table ¹2.

Table ¹2

|

Actuator

name |

Weight of Cylinder,

kg |

Weight of servo-valve and manifold, kg |

Weight of pump and tank, kg |

Actuator weight îf exoskeleton |

|

Knee |

2.02 |

2.64 |

- |

|

|

Hip |

2.06 |

2.64 |

- |

|

|

Ankle |

1.71 |

2.64 |

- |

|

|

Shoulder |

1.91 |

2.64 |

- |

|

|

Elbow |

2.132 |

2.64 |

- |

|

|

Overall

weight |

9.832x2=19.664 |

13.2x2=26.4 |

8+10=18 |

64.1 |

The total weight of the hydraulic drive of

exoskeleton, without taking into account the weight of pipelines, is equal

~64.1kg, which is 46kg less than that of rotary hydraulic actuators.

2.

Mathematical model of hydraulic control system for exoskeleton

2.1.

Electric-hydraulic amplifier (servo valve) (Fig.8)

The equation of voltage in electric circuit

of electromagnet:

, (2.1)

, (2.1)

where ![]() voltage on the output of electronic amplifier;

voltage on the output of electronic amplifier; ![]() active resistance of a control coil of electromagnet;

active resistance of a control coil of electromagnet; ![]() inductance of a coil of electromagnet;

inductance of a coil of electromagnet; ![]() coefficient of back EMF;

coefficient of back EMF; ![]() electric

current in control coil;

electric

current in control coil; ![]() angle of flapper and an anchor of electromagnet, rigidly

connected to it.

angle of flapper and an anchor of electromagnet, rigidly

connected to it.

Value of

coefficient of back EMF is determined according to the following

ratio

, (2.2)

, (2.2)

where ![]() length of the average line of anchor;

length of the average line of anchor; ![]() ;

; ![]() air backlash

between the anchor and the feedback rod.

air backlash

between the anchor and the feedback rod.

The equation of motion of the armature with

flapper

(2.3)

(2.3)

where ![]() moment

of inertia of armature;

moment

of inertia of armature; ![]() coefficient of a viscous amortization of armature;

coefficient of a viscous amortization of armature; ![]() moment of the hydro-dynamical force

moment of the hydro-dynamical force ![]() ,

, ![]() force of electromagnet;

force of electromagnet; ![]() rigidity of a spring of flapper,

rigidity of a spring of flapper,

![]() .

.

![]() , where

, where ![]() force, bending a feedback rod in the time of flapper

angle and spool displacement.

force, bending a feedback rod in the time of flapper

angle and spool displacement.

, where

, where ![]() module of elasticity of the material, of which the

feedback rod is made,

module of elasticity of the material, of which the

feedback rod is made, ![]() moment of inertia of the section of feedback rod

relatively of the main central

axis, perpendicular to the plane of bending force,

moment of inertia of the section of feedback rod

relatively of the main central

axis, perpendicular to the plane of bending force, ![]() deflection of

the end of feedback rod - is

equal to the sum of the deflections caused by the turn of the flapper

relatively of the center O on the angle

deflection of

the end of feedback rod - is

equal to the sum of the deflections caused by the turn of the flapper

relatively of the center O on the angle ![]() and displacement of

and displacement of ![]() of the spool,

of the spool,

![]() .

.

Equation of consumption of working liquid

in the control cascade:

, (2.4)

, (2.4)

where ![]() consumption of working fluid, providing

control of the main spool;

consumption of working fluid, providing

control of the main spool; ![]() square area

of the end face of spool of the main

spool;

square area

of the end face of spool of the main

spool; ![]() displacement

of the spool of the main spool;

displacement

of the spool of the main spool;  coefficient,

which is taking into

account the compressibility of a working

fluid in the face chambers of the main spool;

coefficient,

which is taking into

account the compressibility of a working

fluid in the face chambers of the main spool; ![]() volume of the face chamber of a spool;

volume of the face chamber of a spool; ![]() module

of volumetric elasticity of a working liquid;

module

of volumetric elasticity of a working liquid; ![]() pressure

of liquid in the control chambers under

the end faces of spool of the main

spool.

pressure

of liquid in the control chambers under

the end faces of spool of the main

spool.

Consumption ![]() is defined by known ratios from hydraulics:

is defined by known ratios from hydraulics:

![]()

![]() ,

,

where  conductivity

of a throttle of the servo valve;

conductivity

of a throttle of the servo valve; ![]() pressure of

the pump;

pressure of

the pump; ![]() coefficient of consumption of

liquid through the throttle;

coefficient of consumption of

liquid through the throttle; ![]() square area of the throttle,

square area of the throttle, ![]() specific conductivity of the

jet at neutral position of a flapper,

specific conductivity of the

jet at neutral position of a flapper,

,

, ![]() function,

determining the through passage section between the end face of jet and a

flapper,

function,

determining the through passage section between the end face of jet and a

flapper, ![]() displacement of a flapper,

displacement of a flapper, ![]() distance

between the jet and the flapper at neutral position.

distance

between the jet and the flapper at neutral position.

Equation

of the spool motion in hydraulic amplifier (servo valve)

(2.5)

(2.5)

where ![]() mass of

the spool;

mass of

the spool; ![]() coefficient which is taking into account a

viscous friction in a backlash between the spool and a sleeve;

coefficient which is taking into account a

viscous friction in a backlash between the spool and a sleeve; ![]() rigidity of the spring of the main spool;

rigidity of the spring of the main spool; ![]() the hydro-dynamical force acting on the

spool of the main spool from the side of

working fluid;

the hydro-dynamical force acting on the

spool of the main spool from the side of

working fluid; ![]() force of viscous friction acting on the spool of the main spool;

force of viscous friction acting on the spool of the main spool; ![]() pressure

difference of working liquid at the end faces of the spool of the main spool;

pressure

difference of working liquid at the end faces of the spool of the main spool; ![]() the square area of the end face of the spool

of the servo valve.

the square area of the end face of the spool

of the servo valve.

Equation of consumption of fluid through

the main spool

where ![]() coefficient of consumption of the spool

window(hole);

coefficient of consumption of the spool

window(hole); ![]() diameter of spool of the main spool;

diameter of spool of the main spool; ![]() displacement

of the spool;

displacement

of the spool; ![]() coefficient

of overlapping of a spool

sleeve;

coefficient

of overlapping of a spool

sleeve; ![]() pressure of the pump;

pressure of the pump; ![]() pressure in the cavities of hydraulic

cylinder.

pressure in the cavities of hydraulic

cylinder.

Equation of pressures in the cavities

of hydraulic actuator

(2.6)

(2.6)

Here ![]() the square area of the piston of hydraulic

actuator,

the square area of the piston of hydraulic

actuator, ![]() -

elasticity of a working liquid,

-

elasticity of a working liquid, ![]() -

volume of a liquid under the end face of the piston of a hydraulic actuator,

-

volume of a liquid under the end face of the piston of a hydraulic actuator, ![]() -

factor of compressibility of a working fluid.

-

factor of compressibility of a working fluid.

2.2. Hydraulic actuator (hydraulic

cylinder)

, (3.1)

, (3.1)

where ![]() the mass of the link, attached to a

hydraulic cylinder,

the mass of the link, attached to a

hydraulic cylinder, ![]() displacement of the piston rod of a hydraulic cylinder,

displacement of the piston rod of a hydraulic cylinder, ![]() coefficient

of friction of hydraulic

cylinder,

coefficient

of friction of hydraulic

cylinder, ![]() pressure in the cavities of a hydraulic cylinder,

pressure in the cavities of a hydraulic cylinder, ![]() external force applied to the piston rod of

hydraulic cylinder.

external force applied to the piston rod of

hydraulic cylinder.

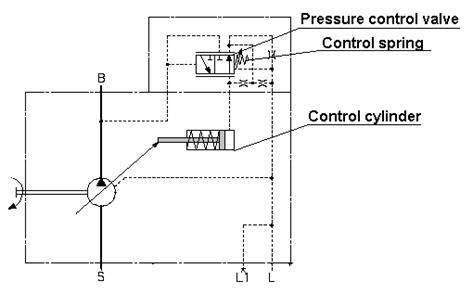

2.3. The pump

with regulator of pressure

Diagram of the pump with a

regulator of pressure is given on fig 4a, 4c. Volume flow of the pump ![]() is determined by the following ratio:

is determined by the following ratio:

![]() , (4.1)

, (4.1)

where ![]() displacement

of the pump;

displacement

of the pump; ![]() maximal angle of swashplate turn;

maximal angle of swashplate turn; ![]() angular

speed of rotation of a shaft of the pump;

angular

speed of rotation of a shaft of the pump; ![]() current value of the angle of turn of the pump

swashplate.

current value of the angle of turn of the pump

swashplate.

Dependence between the displacements of the

piston of the control hydraulic cylinder and the angle of inclination of the

pump swashplate is defined by a expression:

, (4.2)

, (4.2)

where ![]() coordinate,

determining the position of piston of the hydraulic cylinder;

coordinate,

determining the position of piston of the hydraulic cylinder; ![]() maximal

value, which

maximal

value, which ![]() may

accept;

may

accept; ![]() radius of

the basic swashplate of the pump.

radius of

the basic swashplate of the pump.

We consider the pipelines, which connect

the pump with the hydraulic cylinders, short enough, so that we could consider

processes in them without taking into account distribution of parameters of a

working environment along the length of a hydraulic line. Then, proceeding from

the condition of incompressibility of fluid, the equation of consumption in the

pressure head hydraulic line can be written as follows:

(4.3)

(4.3)

where ![]() volumetric

flow of the pump,

volumetric

flow of the pump, ![]() consumption, required for functioning of the

hydraulic drives;

consumption, required for functioning of the

hydraulic drives; ![]() flow

rate of the liquid going for

control;

flow

rate of the liquid going for

control; ![]() coefficient, which is taking into account a compressibility of a

working liquid in the pipelines;

coefficient, which is taking into account a compressibility of a

working liquid in the pipelines; ![]() pressure of

the pump.

pressure of

the pump.

Consumption of fluid, necessary for the

operation of hydraulic drives:

(4.4)

(4.4)

where ![]() flow rate of liquid, consumed by

flow rate of liquid, consumed by ![]() hydraulic drive;

hydraulic drive; ![]() number of

hydraulic drives connected to the pump.

number of

hydraulic drives connected to the pump.

Equation

of motion of the spool of pressure regulator

![]() (4.5)

(4.5)

where ![]() mass of the

spool and of the mobile parts of the pressure regulator spool, attached to it;

mass of the

spool and of the mobile parts of the pressure regulator spool, attached to it; ![]() displacement

of the pressure compensator spool;

displacement

of the pressure compensator spool; ![]() coefficient, which is taking into account the viscous friction in

a backlash between the spool and a sleeve;

coefficient, which is taking into account the viscous friction in

a backlash between the spool and a sleeve; ![]() rigidity of the spring of pressure

compensator;

rigidity of the spring of pressure

compensator; ![]() force of the

preliminary compression of the spring;

force of the

preliminary compression of the spring; ![]() hydro-dynamical

force, acting on the spool from working fluid;

hydro-dynamical

force, acting on the spool from working fluid; ![]() square area of the end face of the pressure

compensator spool.

square area of the end face of the pressure

compensator spool.

Equation

of motion of the pump swashplate and of the control hydraulic

cylinder

![]() (4.6)

(4.6)

where ![]() mass of piston of the control cylinder and

attached to it mobile parts of the mechanism of adjustment of pump flow;

mass of piston of the control cylinder and

attached to it mobile parts of the mechanism of adjustment of pump flow; ![]() coefficients of viscous

friction in the backlashes between the

pistons and the sleeves of the control cylinders;

coefficients of viscous

friction in the backlashes between the

pistons and the sleeves of the control cylinders; ![]() rigidity of

the spring of control cylinder;

rigidity of

the spring of control cylinder; ![]() force of the

preliminary compression of the spring;

force of the

preliminary compression of the spring; ![]() square

areas of piston of the control

hydraulic cylinders;

square

areas of piston of the control

hydraulic cylinders; ![]() total moment

of resistance, applied to the regulating element of the pump,

total moment

of resistance, applied to the regulating element of the pump, ![]() displacement

of the

rod of the control hydraulic cylinder,

displacement

of the

rod of the control hydraulic cylinder, ![]() pressure in

the cavity of the control cylinder.

pressure in

the cavity of the control cylinder.

Pressure in cavity of control cylinder

If y

< 0.5 xîãä. max

- Pressure in control cylinder.

- Pressure in control cylinder.

If y > 0.5 xîãä. max

- flow through the spool of pressure

regulator.

- flow through the spool of pressure

regulator.

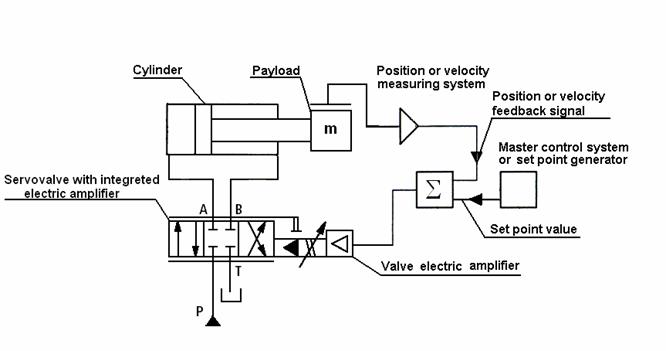

2.4.

Structure of control system (fig.10)

All servo

valves and hydraulic cylinders

are incorporated into a united control system. On this slide the control system

for one hydraulic cylinder is shown.

The

specifying signal from a top level control system and signal from the gauge of

a feedback of the hydraulic cylinder enter to summation device. Feedback signal

has an opposite sign.

Further the signal enters on input of servo

valve amplifier. Resulting signal acts on the coils of servo valve magnet.

Displacement of a spool corresponds to a level of a signal which enters on an

input of servo valve.

The flow of a working fluid and speed of

cylinder accordingly, depends on displacement of a spool of servo valve.

3. Results of modeling

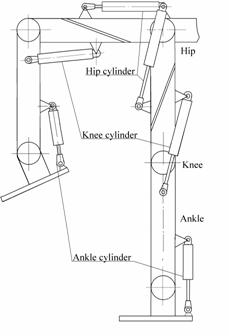

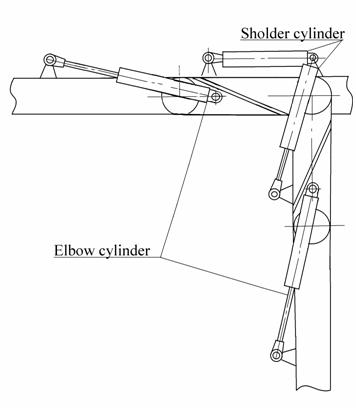

Each leg of exoskeleton has three active

degrees of freedom. Accordingly, three executive hydraulic cylinders should

drive one leg; also three servo valves are required. Two hydraulic cylinders

are required to actuate one hand, and two electric-hydraulic amplifiers

(directional servo valve) to control them. Thus, exoskeleton includes 10

hydraulic cylinders. All of them are powered from one pump.

The system of equations, describing the

functioning of the hydraulic drives for two legs, two hands and the pump with

the pressure regulator, represents the system of the ordinary differential

equations (ODE) of the order of 116, written down in normal form of Cauchy. For

the decision of the ODE system, a Runge-Kutta method of integration, in the

modification of Merson was used.

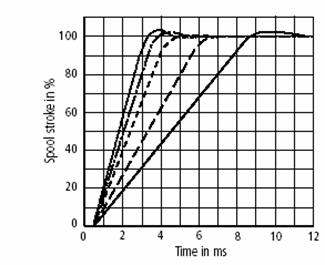

For the definition of adequacy of the

composed mathematical models of the elements, which are included in the

hydraulic drive, a mathematical modeling of the separate elements was carried

out, in particular, - servo valve. Characteristics of servo valves, designed by

the Rexroth company are given in Fig.11, which represent the reaction of servo

valves to a step input electric signal at various values of pressure.

In Fig.12, a similar characteristic,

obtained from modeling of servo valves, is presented. A stepping signal was

applied to the input of servo valves. Supply pressure was set at 210bar.

It is visible from the results that the

simulated performance of the servo valve is similar to the valve

characteristics presented in the manufacturers catalogue.

The program for modeling a hydraulic

control system of exoskeleton allows setting an input voltage as step input or

a sinusoidal signal.

The torque loads acting on the various

joints have been calculated and are presented in Table ¹1. Proceeding from the

geometrical sizes of parts of exoskeleton, the forces, acting on the hydraulic

cylinders, were determined. Based on the assumptions that these values of

torques are the maximum, joint positions, where maximum torque is acting, were determined.

For the legs, it is a position when the angle in the knee joint is equal to

90°.

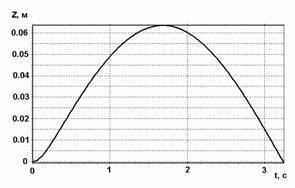

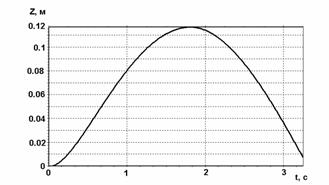

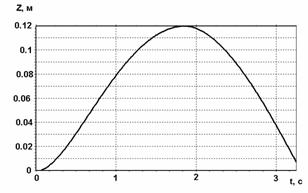

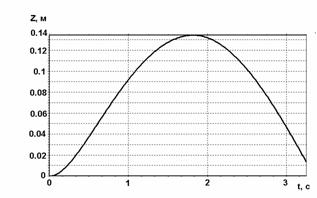

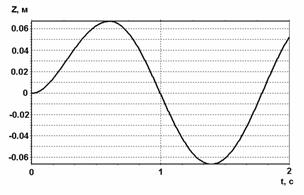

In Fig.13-23, results of modeling of

operation of the hydraulic drive of exoskeleton are given. Two modes of the

most typical motion of the human were chosen for modeling.

The first mode corresponds to the getting

up of the human from the semi-sitting position and a simultaneous rising of

hands. Motion is carried out from the position, where the knee joint is at 90°

w.r.t. the sheen bone, and the thigh bone is in a horizontal position. Final

position corresponds to the movement when the person is in vertical standing

position. Such motion is typical for the human, when he is lifting the loads.

A sinusoidal type voltage was applied to

the input of each tracing drive. The period of a sinusoid corresponds to the

rising up of exoskeleton from the semi-sitting position for 1.5sec and a

knee-bend for the same period. The maximal loadings, acting on the hydraulic

cylinders, have been obtained from the values of twisting moments in each of

the joints, obtained at the Nanyang Technological University of Singapore.

Proceeding from the kinematic diagram of exoskeleton, in which hydraulic

cylinders are used as executive hydraulic actuators, loadings at each of the

joints have been obtained.

Table ¹3

|

The name of a link |

Value of the moment, Í*ì |

Value of force, êÍ |

|

Knee |

370.1 |

2.96 |

|

Hip |

403.8 |

4.038 |

|

Shin |

370.1 |

2.96 |

|

Shoulder |

296.1 |

4.23 |

|

Elbow |

164.4 |

2.342 |

The loading, acting on the hydraulic cylinder, has a constant value.

Values of loadings are given in Table ¹3. While rising up, the hydraulic

cylinders belonging to the opposite sides of exoskeleton move in one phase with

identical speeds. Motions of the rods of hydraulic cylinders are limited to the

maximal values of displacements, obtained from the kinematic diagram of

exoskeleton.

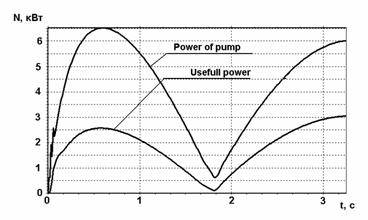

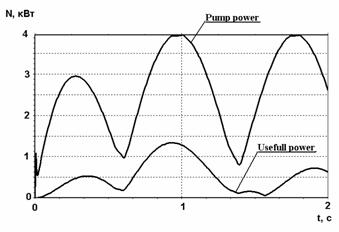

From the diagrams of displacements of the

hydraulic cylinders of the hip (Fig.15), knee (Fig.14), shins (Fig.13), elbow

(Fig.16), and shoulder (Fig.17), it is visible that hydraulic drives trace an

input signal. In Fig.18, the power of the pump and the useful power developed

by the hydraulic cylinders of all parts of exoskeleton are given. This diagram

characterizes the power efficiency of a hydraulic actuator. Apparently from the diagram, the efficiency of a hydraulic

drive averages 50% and higher, that for a hydraulic drive with throttle control

with pressure control pump is quite satisfactory.

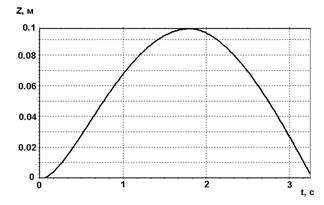

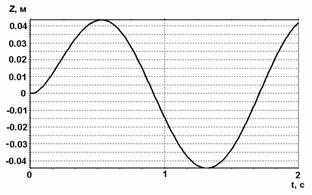

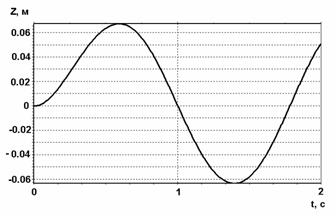

The second mode of motion models the

walking of the human. At motion one leg is in a phase of a support, this phase

is characterized by the relatively high loadings and small speeds, the second

leg is in a phase of carry, which is characterized by the small loadings and

high speeds.

As there is no dependence between the

values of displacements of hydraulic cylinders and the loadings, applied to

them, we have chosen the sine wave law of change of loadings with the amplitude

equal to a maximal loading. The loadings acting on hydraulic cylinders, and

also their speeds may considerably differ at different modes of operation of exoskeleton.

As there are no data about the loading

arising in the joints of exoskeleton during walking, we have chosen, as loading

characteristics, a sine wave law of their change. The loading was changed on a

sinusoid with frequency 2Hz for hydraulic actuators of legs and frequency 1 Hz

for hydraulic actuators of hands. Amplitude of loadings in degrees of

freedom: knee - 1000N, shin - 1200N, hip

- 1500N, shoulder - 1000N, elbow - 1000N. Thus both the input signal and the

loadings, working on the same hydraulic cylinders and belonging to the opposite

sides, change with a 180 degree phase shift. The results

of simulation show that the

hydraulic drive well traces input signals (Fig. 20-22). Displacements of

hydraulic cylinders, belonging to the opposite side, have the same kind of

diagrams, only with an opposite phase.

Power characteristics can be estimated

under the diagram of power of the pump and useful power (Fig.23). The

efficiency is on the average equal 30%. A mathematical modeling of the several

modes with various values of frequency and amplitude was carried out. For all

modes, the hydraulic drive well traces an input signal and has the efficiency

30-40%, that is a good value for a

hydraulic drive with the volume-throttle regulation. More precise results can

be obtained by knowing the loading characteristics for each joint of

exoskeleton.

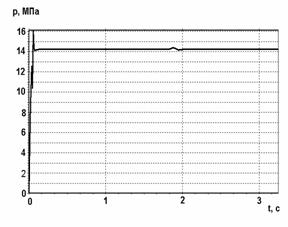

Based on the results obtained from the

above analysis, it is possible to draw the following conclusions. The pump,

working at constant pressure, supports constant pressure in the system.

Therefore such pump may not provide high power characteristics in all range of

changes of working pressure of hydraulic drives of exoskeleton. It is visible

from the power characteristic given on fig 8. If the pressure in hydraulic

cylinders is close to the pressure of adjustment of the pump, then losses in

hydraulic system will be minimal as pressure losses in the servo valves will be

less. Thus, adjustment and control of the working pressure of the pump in

dependence of the mode of motion of exoskeleton, may improve power

characteristics of the hydraulic drive.

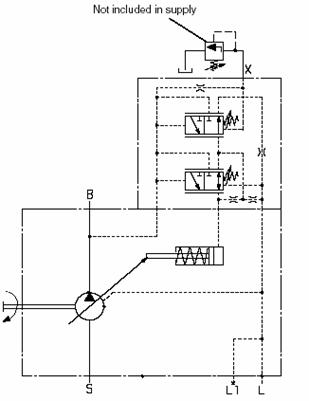

The regulator of pressure may change

working pressure of the pump in a range from 20 up to 210bar. It is provided by

the value of preliminary compression of the pressure limiting spool spring.

During the operation of exoskeleton, there is no accessibility to adjust the

value of spring compression and hence this has to be done through remote

control. The basic hydraulic diagram of such pump is given on Fig.4b.

For example, when exoskeleton overcomes

significant loadings and the high pressure is required in the hydraulic

cylinders, then the regulator of pressure should be adjusted to a high

pressure. Results of modeling of the first mode may serve as an example: when

exoskeleton rises up from a semi-sitting position with loading. During walking

with small loading, high pressure in hydraulic cylinders is not required, the

regulator may be adjusted to a smaller pressure and hence reduce losses of

pressure in servo valves. Thus, by adjusting the regulator pressure of the pump

with reference to the loading and mode of motion, it is possible to optimize

power characteristics.

As a signal for changing working pressure

of the pump may be used signal from the load detector installed at the any limb

of exoskeleton for example at back or at hip. Depending of the value of the

signal from detector it’s possible to define the loads which act on the

cylinders and depending on it install the pump working pressure.

In the whole the offered hydraulic system

provides the functioning of exoskeleton at various modes of operation.

List

of literature

1.

Borovin

G.K. Computer Simulation of Hydraulic Control System of the Walking Machine.

Proceedings 2nd Tampere Intern. Conference on Machine Automat, ICMA'98,

p.p. 179-192.

2.

Borovin

G.K. Computer Simulation of Hydraulic Control System of the Walking Machine.

Preprint KIAM RAS ¹106, Ì., 1995ã. 28p.

(in russian)

3.

Borovin

G.K., Kostyuk A.V. Computer Simulation of Hydraulic Actuator with LS-control of

the Walking Machine. Preprint RIAM RAS

¹54, Ì., 2001ã. 28p.

(in russian)

4.

Borovin

G.K., Kostyuk A.V. Computer Simulation of Hydraulic System of the Walking

Machine. // Proceedings 11nd Conference «Extremal robotics»,

St-Petrsburg, StPSTU, 2001, p.p. 96-106. (in russian)

5.

Borovin

G.K., Kostyuk A.V. Computer Simulation of Hydraulic Control System of the

Walking Machine. // Proceedings Conference «Mobile robots and mechatronny

systems», Ìîscow, ÌSU,

december 2001, 15p. (in russian)

6.

Borovin

G.K., Kostyuk A.V. Computer Simulation of

Hydraulic Control System of the Walking Machine. //

Theory and control systems. 2002, ¹4. (in russian)

7.

Borovin

G.K., Kostyuk A.V. Computer Simulation of dynamics of Hydraulic Actuator of the Walking Machine. ¹8, Ì., 2002, 28p. (in russian)

8.

Manessmann

Rexroth, Brueninghaus Hydromatik. “Product Catalogue Axial Piston Units”, Horb,

Germany, 1997.

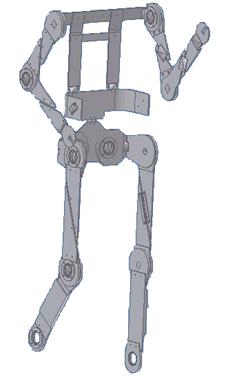

Fig 1. The

kinematic diagram of exoskeleton

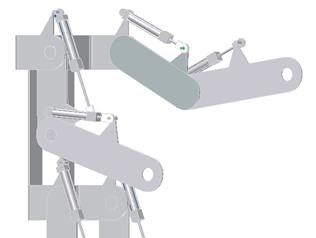

Fig 2. Kinematic diagram of leg of exoskeleton with

the use of hydraulic cylinders

Fig. 2a. Kinematical diagram of exoskeleton with the

use of hydraulic cylinders (passive degrees of freedom are not shown)

Fig 3. Kinematic diagram of a shoulder and a hand with

application of hydraulic cylinders

Fig. 3a. Kinematic diagram of the hands and shoulders

with application of hydraulic cylinders (passive degrees of freedom are not

shown)

Fig 3b. Legs

of exoskeleton with servo valves and hydraulic cylinders

Fig.

4a. The basic hydraulic circuit of the pump with pressure control

Fig. 4b. The basic hydraulic circuit of the pump with the

pressure regulator with remote

control

Fig. 4c. Scheme of the pump with

pressure regulator

Fig.5a. The characteristic of the hydraulic drive

working with pump with

pressure regulator

Fig. 5b. The characteristic of the pump working on

constant pressure

Fig. 6. The circuit of an arrangement of the pump

inside a tank

Fig. 7. The

electric-hydraulic amplifier of type (servo directional valve)

Fig. 8. The diagram for calculation of the electric-hydraulic

amplifier (servo valve) with a force feedback from a

spool to a flapper

Fig 9. The basic hydraulic circuit of exoskeleton

Fig.10. Diagram of hydraulic driver control system

Fig 11. Characteristic of servo valve at step input

influence

|

Fig.12.

Diagram of displacement of the

Fig.13. Displacement of the shin

spool of servo valve at step hydraulic cylinder at

rising up

input influence and knee-bending of exoskeleton |

|

Fig.14. Displacement of the knee Fig.15. Displacement of

the hip hydraulic cylinder at rising up

and hydraulic

cylinder at rising up knee-bending of exoskeleton and knee-bending of exoskeleton |

|

Fig.16. Displacement

of the elbow Fig.17.

Displacement of a shoulder

hydraulic cylinder at raising and hydraulic cylinder at a

raising and

lowering of hands of exoskeleton lowering of hands of

exoskeleton

|

|

Fig.18. Diagrams of the power of the pump Fig.19. Diagram of pressure of the and useful power of all hydraulic pump cylinders |

|

Fig.20. Displacement of the hip Fig.21. The diagram of the

displacement hydraulic cylinder at walking of a shin

hydraulic cylinder at walking |

|

Fig. 22. Displacement of a knee Fig.23. Diagrams of

power of the pump hydraulic cylinder at walking and useful power of the hydraulic

cylinders of exoskeleton |