Stochastic simulation of nano-scale surface and near surface region modification:

high-temperature blistering and thin films formation

|

Development of high-temperature blistering under the

influence of plasma or ion beams on solid surface.

Introduction.

Understanding of processes of interaction between

solids surfaces and plasma has significance for development technologies which

have concern with cosmophysics, controlled thermonuclear fusion,

nanotechnologies. Such problems as blistering, flaking and physical processes,

which take place under irradiation of solids surfaces by ions beams. All these

processes result in solids properties change, plasma pollution and plasma properties

change. Computer simulation of interaction between plasma and solids surfaces

takes on special significance in connection with high price, labor-consuming

and complexity of laboratory experiments with plasma.

Fluctuation stage of high-temperature blistering is examined in this

work. Formation of gas-vacancy pores, which were named blisters, into Ni crystal lattice under the influence

of He ions is discussed. He ions have energy from 10 keV to 100

MeV, radiation dose is from 1016 to 1019 ions/sm2,

the temperature of sample material T is ![]() , Tmelt

is melting temperature of Ni.

Fluctuation stage is very short-range. Its duration is approximately 10-4

sec. But this stage is defined determinates all following peculiarities of

blistering [1-8].

, Tmelt

is melting temperature of Ni.

Fluctuation stage is very short-range. Its duration is approximately 10-4

sec. But this stage is defined determinates all following peculiarities of

blistering [1-8].

Model of blistering. Kinetic

and stochastic equations of model.

Stochastic model of fluctuation stage

of high-temperature blistering has been suggested. The model under discussion

is based on Brownian motion model. Blistering is considered as first-order

phase transition on its fluctuation stage. Bubbles have size approximately of

several angstorm and this kind of defects is considered Brownian particle with

sphere form and variable mass. Blisters can interact with each other, with

solid lattice and with solid surface. Let us use scheme of splitting on

physical processes: bubbles formation and its stochastic motion. The evolution

of bubbles presented as a superposition of the stochastic processes of size

increase and bubbles stochastic motion in crystalline lattice. It is possible

since processes of bubble size increase and bubble migration in lattice have

appreciably different time scales. Characteristic time for blisters size

increasing is 10-9 sec, typical time for its migration in lattice is

10-8 sec. Kinetic equations of Brownian motion model can be solved

by the method of stochastic analog.

The

main idea of the method is change of kinetic equations its stochastic analogs

and solve stochastic differential equations [9]. Authors apply not only

splitting on physical processes but splitting on coordinate too [1-8], because

we have taken into account the interaction of all defects with surface.

Received kinetic equation and its stochastic analogs display below. Let us

present our model by the system of two kinetic partial differential equations

of Fokker-Planck-Kolmogorov and Smoluchovskiy-Kramers kinds.

The

first equation under consideration (Kinetic Fokker-Planck-Kolmogorov equation

for evaluation of blister size) is follow:

![]()

![]()

g is number of He atoms in

bubble, ![]() is distribution

function,

is distribution

function, ![]() is diffusion

coefficient in phase space of all possible bubble sizes,

is diffusion

coefficient in phase space of all possible bubble sizes, ![]() is Gibbs potential of

bubble (cluster) formation.

is Gibbs potential of

bubble (cluster) formation.

The

equation Ito in Stratonovich form, which is equation of stochastic analog of

Fokker-Planck-Kolmogorov equation, is presented below

Tk is

full time of computation, ![]() is stochastic

function,

is stochastic

function,  . The same equation can be formulated for vacancies into

lattice, but we are examined only He atoms for simplicity of presentation.

. The same equation can be formulated for vacancies into

lattice, but we are examined only He atoms for simplicity of presentation.

![]()

![]()

![]()

We

have taken into account the difference between chemical potentials of two phase

(![]() ), surface tension on bubble –metal surface (b), elastic force of lattice reaction (c) [3-8], inequality between

locations in lattice points and internodes (

), surface tension on bubble –metal surface (b), elastic force of lattice reaction (c) [3-8], inequality between

locations in lattice points and internodes (![]() ), relcases in crystalline lattice (

), relcases in crystalline lattice (![]() ) [3-8]. Nbr

is number single relcases,

) [3-8]. Nbr

is number single relcases, ![]() is energy of single

relcase,

is energy of single

relcase, ![]() is binding energy in

lattice.

is binding energy in

lattice.  , gcr is

critical size of bubble,

, gcr is

critical size of bubble, ![]() ,

, ![]() . The choosen of initial state of clusterization depends on

fluctuation instability of system.

. The choosen of initial state of clusterization depends on

fluctuation instability of system.

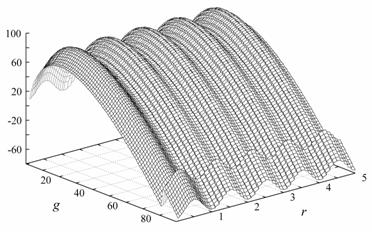

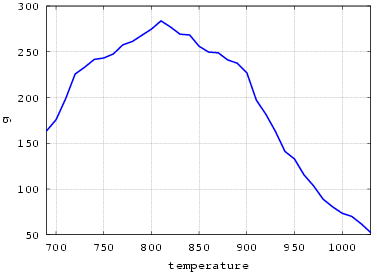

The

Gibbs potential has form which is presented on figure below.

The dependence of Gibbs potential (Joule/atom)

from the both blister size (g) and position in crystal lattice (r). Blister

size is measured in number of helium atoms in bubble. r is measured in lattice parameter of

Ni (lattice parameter of Ni a=3.5 Å).

The break on g »80 corresponds the first break of

due to increasing of blister size.

Fig.2

One-dimensional

Gibbs energy versus cluster size. This figure illustrated the region of

instability of

DF for fluctuation-dependent stochastic process

{g(t), t

³

0}.

Cluster

migration into lattice can be modelized by 3-dimentional Brownian motion. The

kinetic equation for motion of blisters is following

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() ,

, ![]()

![]()

![]() .

.

We

consider that blister comes out surface and dies on it if z£ z2.

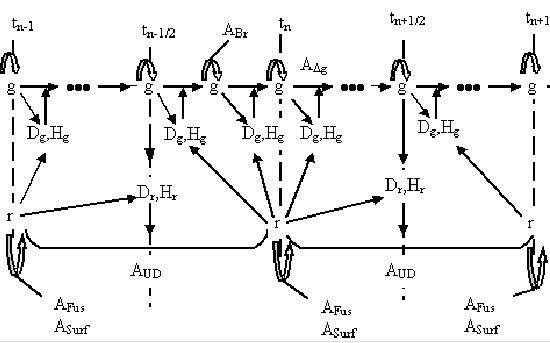

Fig.

3 presents examined region schematically.

x,y,z are measured in

lattice parameter, zmin is surface, zmax = 2 Rp,

Rp is middle depth of projection run, origin of coordinates is in point {x=0, y=0, z=0}, ![]() is kinetic

distribution function,

is kinetic

distribution function, ![]() is diffusion

coefficient in lattice space, Mg is mass of blister,

is diffusion

coefficient in lattice space, Mg is mass of blister, ![]() is dissipative factor,

is dissipative factor,

![]()

![]() is

potential of indirect interaction between bubbles by way of acoustic phonons

and Friedel oscillation of electron density in the case of metal substrate

[10].

is

potential of indirect interaction between bubbles by way of acoustic phonons

and Friedel oscillation of electron density in the case of metal substrate

[10].

where ar, br, cr are fitting coefficient

of model.

where ar, br, cr are fitting coefficient

of model.

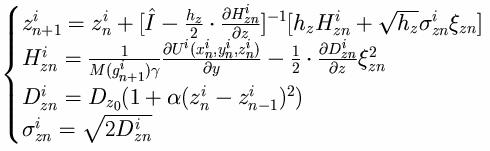

The

stochastic analog of the kinetic equation for one coordinate is following:

Em

is energy of migration, dW is

increment of Wiener stochastic process. For z

coordinate U=Ubb+Ubs,

Ubb is potential of interaction between bubbles and Ubz is interaction potential

between bubble and surface.

Fig.4

The fusion of blister is considered in model under discussion. The

fusion of two bubbles is made approximately. Two bubbles interflow if following

condition is realized: distance between centers of mass bubbles is less than

sum of blisters radiuses and some model parameter Df. 0 £ Df £a, a is lattice parameter [3-8].

Fig.

5

Used

model allows to find the distribution functions of bubbles from size and

pozition in lattice at different moment of time.

Such

characteristics as middle size of bubbles, porosity of layers, tension in

layers, number of blasted blisters and dependence of these values from time can

be find as a result of processing of these distribution functions.

The modified Artem’ev method [11, 3-8] has been used for solution of

stochastic differential equations.

The numerical scheme is presented below:

Fig.6

here ADg –operator of size change; ABr

–operator of lattice broken; AUD- operator of diffusion, bubbles

interaction and interaction between bubble and surface; AFus-

operator of fusion; ASurf – operator of exit on surface, reflection

from it or destruction on it.

We used 106 trajectories of

stochastic process for receiving of physical results, which are presented

below.

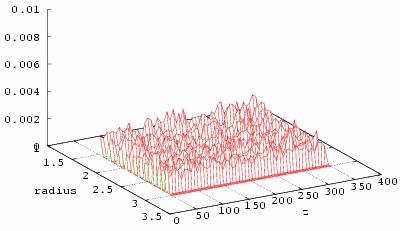

Two

dimensional distribution function, initial time Blister radius, Å Distance from surface, lattice parameter

Fig.7

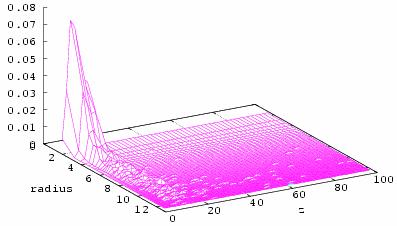

Two dimensional distribution function, moment of finish of calculation Blister radius, Å Distance from surface, lattice parameter

Fig.8

Dispersion of blister size N-number of trajectories Fig.9 Time, step of algorithm Fig. 10 Time, step of algorithm

![]()

![]()

Distance from surface to center of blister, lattice parameter Fig. 11 Time, step of algorithm

blister with number i belongs to j-layer

blister with number i belongs to j-layerwhere V is volume of all sample, Vj is volume of layer with number j, gi

is size of blister at examined time moment, g0 is size of blister at

initial time, f(g,z,t) is distribution function at examined time, f(g) is

distribution function at initial time, z is distance between surface and centre of

blister, z is measured in lattice parameter, z=0 is surface under irradiation.

initial time

moment of time finish of calculation

Fig. 12

Fig.

13

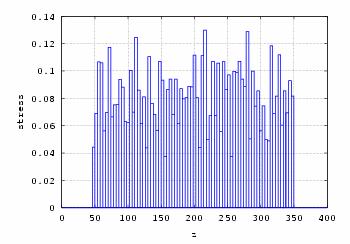

The dependence of stress from layer

Fig. 14

Stress, s0

Stress, s0 initial

time

time of finish of

calculation

Fig. 15

Stress, s0 zÎ[0;0.25 Rp] t=0.25 Tfinish

coordinate y, lattice parameter coordinate

х, lattice

parameter

Fig. 16

Stress, s0 zÎ[0;0.25 Rp] t=Tfinish coordinate

х, lattice

parameter y

coordinate, lattice parameter Fig. 17

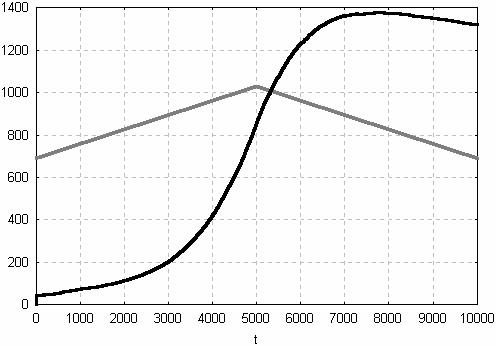

The dependence of blister size at finish of calculation from different

temperatures

Blister size, Number of He atoms in blister

Temperature, К

Fig. 18

Blister size

Change of themperature during calculation

Fig. 19

Conclusions.

The

most interesting results of these experiments are:

1.

the new kinetic and

stochastic model of fluctuation stage of blistering are created;

2.

the Artem’ev method is

modified for solution of system of stochastic equation with

functional-coefficients;

3.

the complex of programs for

simulation of fluctuation stage of blistering is elaborated;

4.

distribution functions of

bubbles from sizes and coordinates are nonequilibrium during fluctuation stage;

5.

blisters chains are formed

athwart to incident flux of ions;

6.

quasi-lattice of bubbles is

observed;

7.

blister size can reach 12

Å during fluctuation stage, decrease of growth rate after bubble size 10

Å is connected with increase of crystal lattice damage;

8.

bubbles size reaches maximum

when relation of solid temperature to melting temperature of materials is 0.47;

9.

the bubbles migration into

the direction of surface under irradiation if bubble radius is less than

10.

the greatest porosity and

greatest tensions are observed on depths of ~ 0.85 Rp and ~

0.35Rp, Rp is middle depth of projection run;

11.

approximately 15% of

blisters destroyed on solid surface during fluctuating stage.

Thin films formation under the influence of plasma or

ion beams on solid surface.

Introduction.

Numerical

simulation of adatoms clusterization of solids surfaces under plasma influence

is interesting for creation of thin films and covers with necessary behaviour.

Release coatings, anticorrosion covers, nano-functional, resistant to pollution

and ultrahydrophobic coverings are examples of coatings with defined

properties. The study of nano-capsules and ions implantation into near surface

layers, interstitial atoms and formed clusters migrations from solids to

surface is very important for creation of self-repair materials and coves. The

fluctuation stage of thin films formation is examined in this paper.

Model, kinetic and

stochastic equations of model.

The

modified by ions substrate is choosen metal W. Let us consider this problem

using stochastic approach, similar has been used in blistering model, which had

been presented in [1-8]. The surface of metal substrate has been contacted with

vapour of Ni. For example the thin film material can be examined liquid Ni

metal. Thin films behaviour differs from behaviour of solids consisting from

same material. Cover formation includes adsorption, creation of new phase

islands, increase/decrease of them sizes, motion of new phase islands on

surface and others processes. The initial fluctuating stage of thin films

formation is of great important, parameters of processes during this stage

determine the behaviour of covers in many respects. The duration of this stage

is approximately 10-4 sec. The island of new phase (cluster of

adatoms) consists of deposited atoms of evaporated material predominantly and

small number of implanted atoms which went on surface as result as diffusion on

material lattice. Increasing or decreasing of island (i.e. cluster of adatoms)

depends on fluctuations during its sizes stochastic changes and jump-like

fusion of clusters. Initial stage of cover formation has been considered as the

geterogeneous first-order phase transformation (from vapour to liquid on the

substrate), here have not be examined chemical reactions during fluctuation

stage of this phase transition. Let us model the stochastic diffusion of

islands on the surface as a brownian motion adapted for flat coordinate

configuration. Following previous experience of computer simulation [1-8] we

can use stochastic analog approach as well physical processes splitting. The

sizes of islands formation and stochastic migration of islands processes have

the different time of development. So, typical time for change of island size

10-8 sec and for migration on substrate surface 10-7

sec. The moving of clusters on surface is realizes under

exposure of surface potential and long-range indirect potentials of interaction

of clusters each with other.

The

phase transition on the surface can be formulated using fundamental Leontovich

equation, which is presented by the system of two kinetic equations of

Kolmogorov-Feller and Smolukhovskii-Kramers kinds (which have been received

after splitting procedure of problem):

![]()

![]()

![]()

![]()

![]()

where

S

a

is source of vapour which generats ion with fa

- maxwell ion function, which is characterized by

temperature 2500 K, g is the number

of atoms which is consisted in island-clusters, ![]() is the diffusion

coefficient in the space of cluster sizes;

is the diffusion

coefficient in the space of cluster sizes; ![]() is the bubble size

distribution function – the probability to find the cluster with size g in interval of values of g [g,g+Dg],

is the bubble size

distribution function – the probability to find the cluster with size g in interval of values of g [g,g+Dg], ![]() is the Gibbs energy, Mg is the cluster mass, g is constant of friction, distribution function

is the Gibbs energy, Mg is the cluster mass, g is constant of friction, distribution function ![]() is the islands space

function

is the islands space

function ![]() is the position

of cluster mass centre in orthogonal coordinates system:

is the position

of cluster mass centre in orthogonal coordinates system: ![]() = -200,

= -200, ![]() = 200,

= 200, ![]() = -200,

= -200, ![]() = 200,

= 200,

![]() is the potential of

long-range clusters interaction between them through phonons and oscillation of

electron density. The form of potential is similar [3-8], firstly this

interaction had been formulated by [10] in problem of light defect

clusterization into lattice.

is the potential of

long-range clusters interaction between them through phonons and oscillation of

electron density. The form of potential is similar [3-8], firstly this

interaction had been formulated by [10] in problem of light defect

clusterization into lattice.

![]()

ar, br,

cr is model

parameters.

The non-linear functional coefficient of equation  is stochastic

diffusion coefficient of islands on surface, D0 is coefficient diffusion of adatom on surface, Em is bonding energy of

adatom with surface,

is stochastic

diffusion coefficient of islands on surface, D0 is coefficient diffusion of adatom on surface, Em is bonding energy of

adatom with surface, ![]() is parameter of model.

is parameter of model.

The Gibbs energy looks like following:

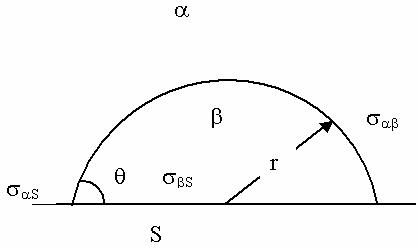

Fig.

20 The scheme of new phase island on solid surface.

where

,

, ![]() is difference of

chemical potential of phases (vapor and liquid),

is difference of

chemical potential of phases (vapor and liquid), ![]() ,

, ![]() are surface

tension between Ni vapour-liquid Ni in island, liquid Ni island-W, Ni vapour-W,

c is coefficient of elastic lattice

reaction,

are surface

tension between Ni vapour-liquid Ni in island, liquid Ni island-W, Ni vapour-W,

c is coefficient of elastic lattice

reaction, ![]() is the energy required

for breaking of a single bond with lattice, in our case it is value from

laboratory experiment,

is the energy required

for breaking of a single bond with lattice, in our case it is value from

laboratory experiment, ![]() is the bond energy in

lattice,

is the bond energy in

lattice, ![]() , Nb is

number of broken bonds.

, Nb is

number of broken bonds. ![]() shows influence of

substrate lattice and the fact that influence of substrate lattice decreases

when cluster size increases, when cluster locates in point (x,y)

shows influence of

substrate lattice and the fact that influence of substrate lattice decreases

when cluster size increases, when cluster locates in point (x,y)  , here ax

and ay are lattice

parameter on x and y axes, in our case ax=ay=a, a

is lattice parameter of W. Y is model function which is depended on islands sizes, also the

dislocation of the lattice. If cluster locates in point (x,y) then

, here ax

and ay are lattice

parameter on x and y axes, in our case ax=ay=a, a

is lattice parameter of W. Y is model function which is depended on islands sizes, also the

dislocation of the lattice. If cluster locates in point (x,y) then ![]() ~

~ ![]() , otherwise Y~1, the dislocation can be simulated by Y decreasing in same times. All parameters are non-dimensional, it is

traditional for kinetic theory. The

, otherwise Y~1, the dislocation can be simulated by Y decreasing in same times. All parameters are non-dimensional, it is

traditional for kinetic theory. The ![]() and

and ![]() are nonlinear

functional-coefficients which dependence on clusters sizes.

are nonlinear

functional-coefficients which dependence on clusters sizes.

Gibbs

energy includes difference of chemical potential of vapour and liquid phases,

interface tensions on surfaces of condensate- vapour, condensate- substrate,

substrate- vapour, elastic force of lattice and possibility of relcases of part

of connections in lattice, non-equivalence of islands positions on surface. The

heterogeneous condensation is considered on substrate and on clusters surfaces.

Joul/atom

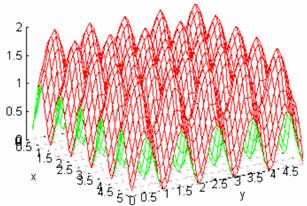

Fig. 21. The ![]() without

cluster and dislocation is presented in this figure.

without

cluster and dislocation is presented in this figure.

Fig. 22. This figure presents

![]() when the cluster has size equated two lattice parameters and

located in place with coordinates (3;2). x

and y measured in lattice parameters

of W.

when the cluster has size equated two lattice parameters and

located in place with coordinates (3;2). x

and y measured in lattice parameters

of W.

Joule/adatom

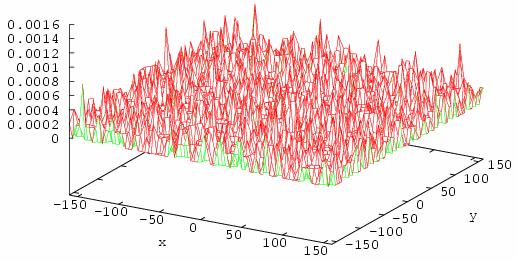

Fig. 23 This figure presents

![]() near dislocation which

placement can be described by equation y=x

near dislocation which

placement can be described by equation y=x

For

solve these kinetic equations authors used original computational method of

stochastic simulation [9, 12, 1-8]. The main idea of this method is using the

fundamental qualities of partial differential equations Fokker-Planck kind, which give us possibility to present

physical problem by set Ito-Stratonovich equations with functional-

coefficients. SDE are equivalent to kinetic problem formulated with Fokker-Planck formalism. We replace of kinetic

equation by these stochastic analogs – stochastic differential stochastic

Ito-Stratonovich equations /SDE/. The SDE (analogue of equation for fr(g,t)) looks like

following:

![]()

where Tk

is duration of fluctuating stage, x is stochastic function related with increment of

Wiener process, g0 is initial cluster size, gmin and gmax

are borders of unstable region of initial size of cluster which calculated from

![]() , T is temperature

of cluster,

, T is temperature

of cluster, ![]() , gcr is critical size.

, gcr is critical size.

For solve of systems of stochastic equations authors

modified Artemiev’s method [11]; it is a second-order accuracy method, with

infinite domain of stability. For all i=1,2,...106 trajectories of

Wiener stochastic process we can use the following determination of the

function ![]() , where a1 и

a2 are random numbers evenly distributed in

region (0,1).

, where a1 и

a2 are random numbers evenly distributed in

region (0,1).

Fig. 24 presents of calculation scheme.

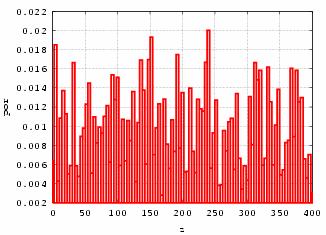

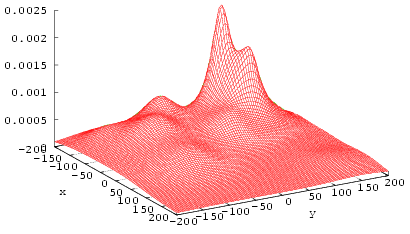

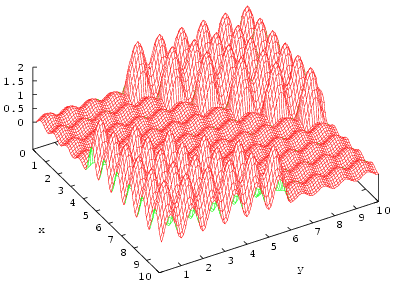

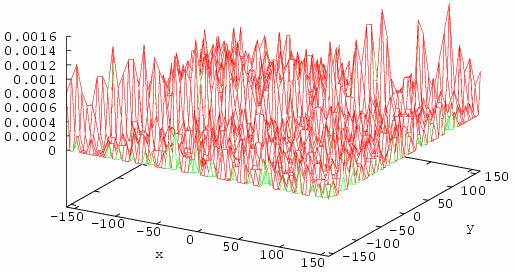

Fig. 25. The distribution function of islands from x

and y coordinate at initial time moment is shown on this figure. The

distribution function is normalize on 1.

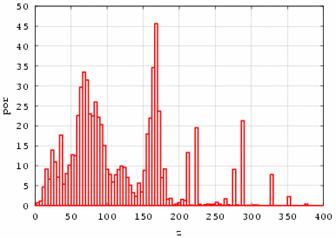

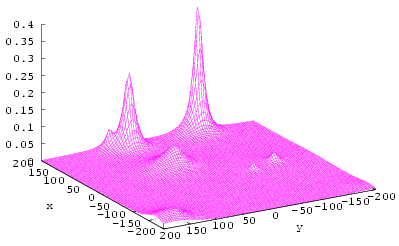

Fig. 26. The distribution function of islands from x

and y coordinate at finish moment of time is presented on this figure.

finish moment of time initial time moment

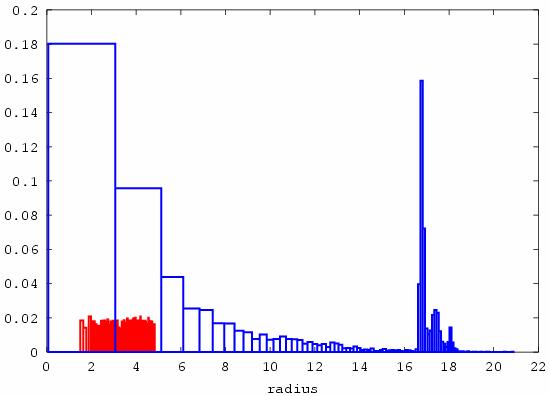

Fig. 27. This figure presents distribution function of

clusters from size at initial and finish moments of time. The radius in lattice

parameters of W is shown on abscissa axis.

Fig. 28. The snap of surface at finish moment of time

is presented in this figure.

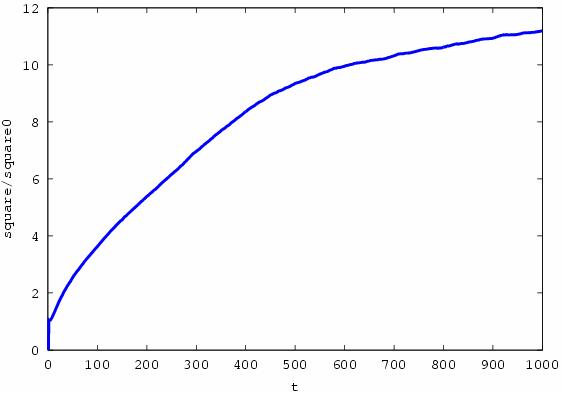

Fig. 29. The ratio of total islands square from total

islands square at initial time moment is shown. The time in txy

is put off on abscissa axis.

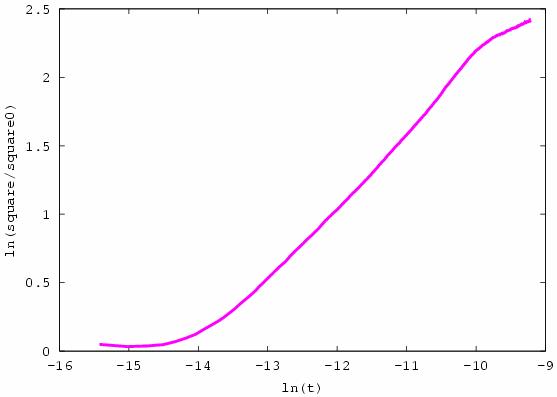

Fig. 30. This figure describes change of logarithm of

the ratio of total islands square from total islands square at initial time

moment depend on logarithm of time. Time is supposed in sec.

Fig. 31. presents the dependence of rate of stress in

layer at finish time to stress on surface at initial time moment from layer

depth. Z is layer depth measured in lattice parameter of W.

Conclusions

As we can see from presented pictures, radius of

islands distribute uniformly from 5.31 Å to 17.7 Å at initial time

moment. From 10-4 sec form of distribution function shows that two

most probably radiuses exist. The first size (~ 16 Å) is similar to critical size and

corresponds to newly form clusters, second size (~ 61 Å) corresponds to islands which grow

including at the expense of fusions during calculation.

The number of islands placed near linear dislocation

is more than clusters number far from it approximately at 8 times. So, the thin

films formation begins on defects of surface such as dislocations.

Three stage of cover formation during fluctuation

stage are discovered. The first stage lasts from 0 to 8×10-7 sec, it is stage of slow development.

The second stage continues from 8×10-7 sec to 5×10-5 sec and it is stage of quick growth of

thin film. The third stage lasts from 5×10-5 sec to 10-4 sec and it is

notable for deceleration of growth velocity. At that, cover square increases at

11 times approximately with respect to cover square at initial moment of time.

The calculations confirm that influence of cover

reaches on depth of 5 lattice parameters approximately. At the same time,

stress on surface and near surface layers caused by thin film formation does

not exceed the stress caused by blisters development. The stress on surface

connected with cover growth increase at 21 times during fluctuating stage.

Acknowledgments

The

work is partially supported by Russian Science Support Foundation, RFBR grant

02-01-01004, the program "Nanoparticles and nanotechnology" by

Department of Mathematical Sciences RAS 3.5 and scientific school 1388.2003.2.

References.

1.

Bondareva A.L., Zmievskaya

G.I.// Mathematical Models of Non-Linear Excitations, Transfer, Dynamics and

Control in Condensed Systems and Other Media / Ed. L. Uvarova. ¾ N. Y.: Plenum Publ. Co. 1998. P 241-250.

2.

Bondareva A.L., Zmievskaya

G.I. // Proceeding. XXV ICPIG, 2001,

3.

Bondareva A.L., Zmievskaya

G.I. //

4.

Bondareva A.L., Zmievskaya

G.I.//

5.

Bondareva A.L., Zmievskaya

G.I. // Thermophysics and Aeromechanics, Vol. 10, No. 2, 2003, pp. 255-265

6.

Bondareva A.L., Zmievskaya

G.I.// Proc. of ICPIG XXVI July 15-20

2003

7.

Bondareva A.L., Zmievskaya

G.I.// Proc. of 16th International Symposium on Plasma Chemistry.

8.

Bondareva A.L. Stochastic

simulation of fluctuating stage of high-temperature blistering, Ph.D. thesis,

9.

Zmievskaya G.I.// Plasma

Physics Reports, 1997. Vol. 23, No. 4, P. 45.

10.

Morozov A.I., Ovchankov

P.A., Sigov A.S. in: Coll. of Research Papers, ed. by Yu.S. Sigov, Moscow,

Keldysh IAM AS

11.

Artemiev S.S., Averina T.A.

Numerical analysis of systems of ordinary and stochastic differential

equations.-Utrecht, The Netherlands. 1997. P. 176

12.

Zmievskaya G.I. // Rarefied

Gas Dynamics, AIAA edited by Shizgal, B.D. and Weaver, D.P. Vol. 159

Washington, DC, 1994, pp. 371-383